Factory

WHERE PRECISION MEETS PURITY

Inside our factory, nature’s finest resource transforms into world-class coconut shell briquettes — engineered with integrity, passion, and precision.

At Nayyara Mitra Kalendra, we take pride in combining traditional know-how with precise craftsmanship. Two high-performance lines, custom-engineered for stability and efficiency, deliver consistent output up to 300 tons per month so our global partners receive a smooth, reliable supply.

Facility Overview

Dual production lines with custom machinery

We merge traditional charcoal expertise with custom-built mixers, presses, ovens, and cooling zones to stabilise every stage of production. Each line features rotary screening, diskmill crushing, 200 kg mixers, double blending, wire-cut molding, and high-capacity ovens tuned for repeatable results.

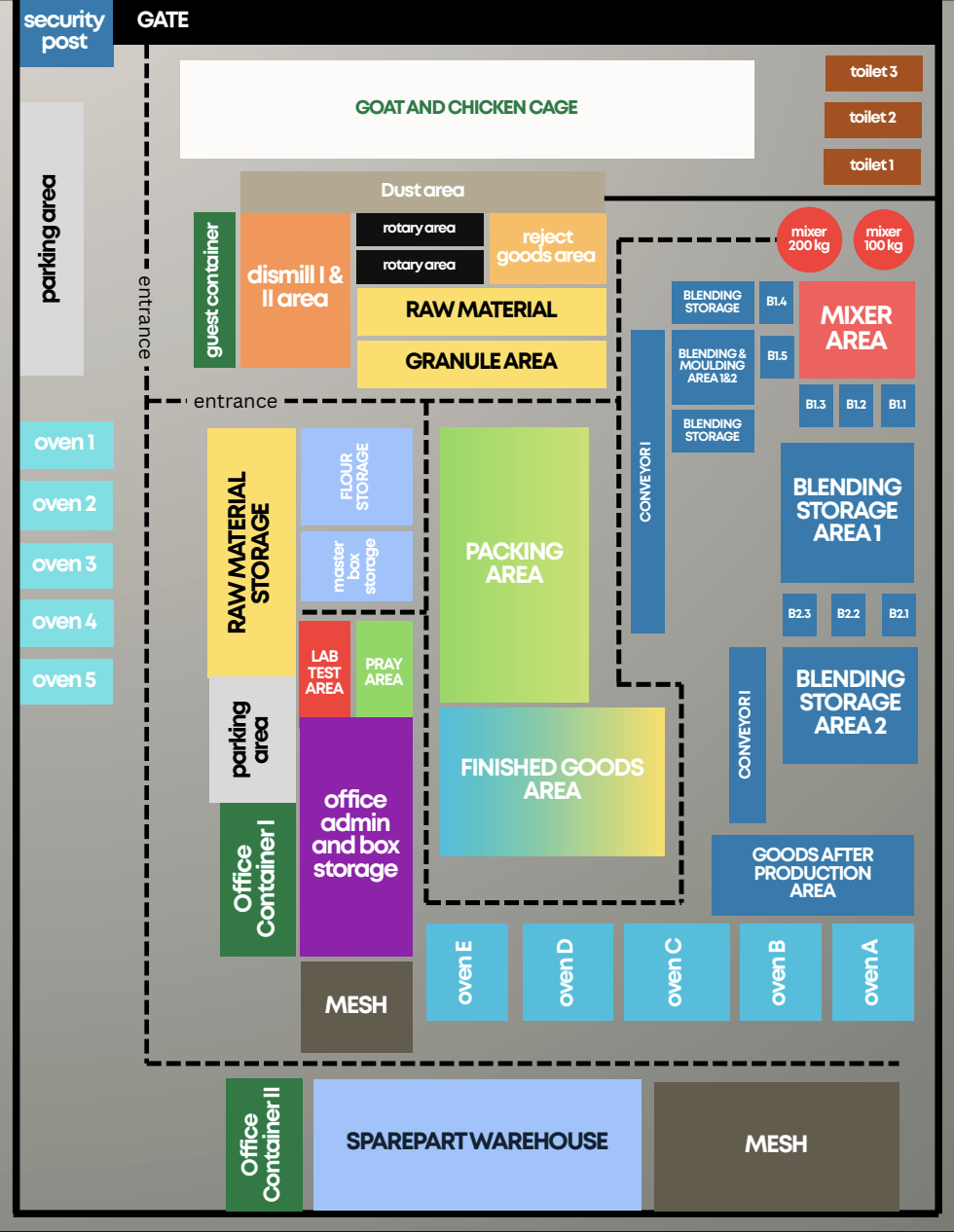

Integrated Layout

Raw material yards, rotary screening, mixing, molding, cooling, laboratory, and finished goods areas mapped for seamless flow.

Climate Control

Controlled ovens (80–90°C) with 10 racks × 50 trays, plus weathering zones to stabilise moisture before packing.

Core Capabilities

Dedicated production lines operating in tandem for flexible scheduling.

Monthly output combining cube, hexagonal, flat, and Kaloud formats.

Continuous kiln monitoring and maintenance coverage to reduce downtime.

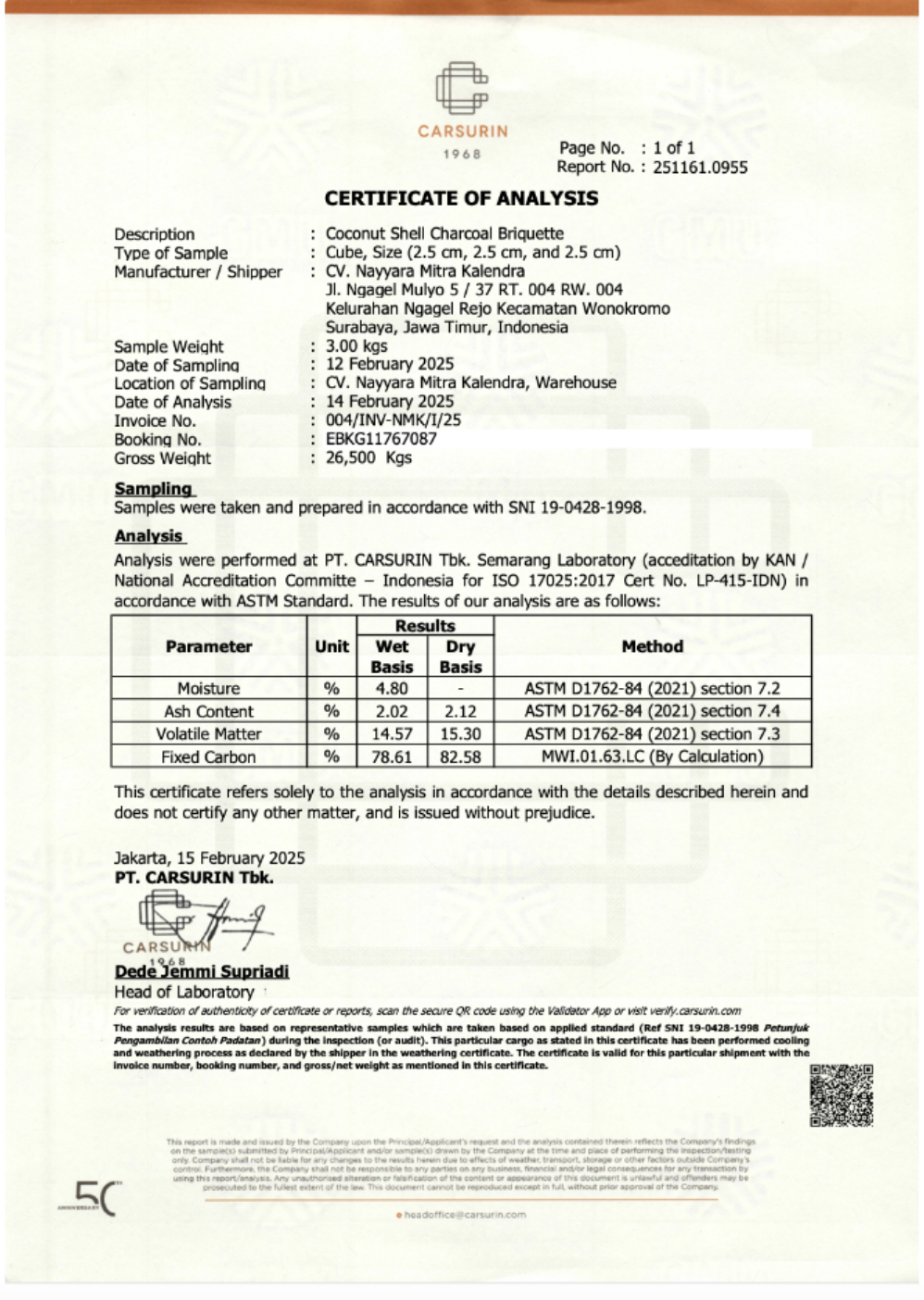

Quality Assurance

Tested to meet international standards

Each briquette is assessed for burn stability, moisture control, and dimensional accuracy so every pallet delivers the same clean performance. Traceability tags accompany every batch from shell sourcing to final shipment.

Shell-to-shipment traceability

Batch IDs, laboratory reports, and packing records are linked to export documentation for transparent audits.

Production Journey

From shell to shipment in 12 controlled steps

- 1. Screening

- 2. Re-sorting

- 3. Crushing (≤3 mm)

- 4. Mixing with 5% tapioca & water

- 5. Blending (twice)

- 6. Molding & cutting (wire cut)

- 7. Pre-cooling on trays (≈4 h)

- 8. Drying in ovens (48–72 h)

- 9. Cooling & weathering (1–2 days + 14 day rest)

- 10. Briquette test (post oven)

- 11. Re-burn test & packing

- 12. Warehouse staging & container loading

Quality & Traceability

Batch-Level Monitoring

Each production lot is tagged with sourcing, processing, and QA data—covering moisture, ash, and burn tests for CARSURIN-aligned traceability.

Laboratory Testing

In-house lab conducts initial burn tests post-oven and re-burn tests prior to packing to lock in performance targets.

Sustainability

Closed-loop heat recovery and coconut-shell valorisation reduce waste and emissions while supporting local communities.

Factory Layout

Thoughtfully zoned for efficiency & safety

- Oven blocks A–E with temperature logging

- Dedicated mixer rooms (100 kg & 200 kg units)

- Lab test zone for moisture, ash, and burn analysis

- Raw material warehouses and spare-part storage

- Conveyor and wire-cut stations for precision sizing

- Cooling yards with weathering racks and pallet covers

- Finished goods warehouse with pallet wrapping

- Loading dock designed for container stuffing efficiency

Affiliations

Supported by trusted partners & certifiers

We collaborate with certification bodies, logistics operators, and financial institutions to keep every shipment compliant and on schedule.

Schedule a Visit

Explore our production capability first-hand

We welcome partners to audit our facility, witness burn tests, and align on operational requirements. Arrange an in-person or virtual factory walkthrough with our export team.